Manhole covers, when not selected, installed and maintained in the…

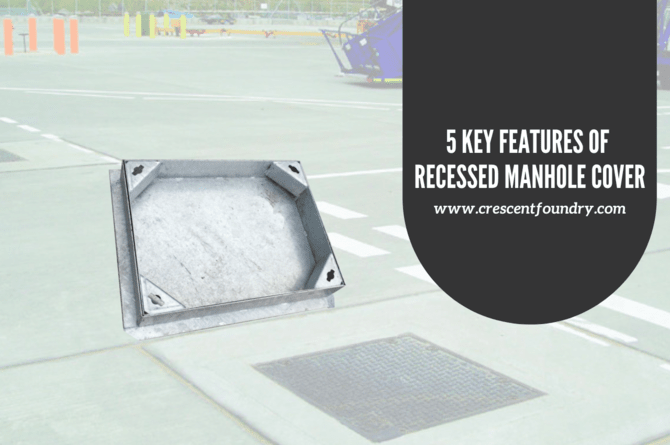

5 Key Features and Specifications of Recessed Manhole Cover

From the city roads to the suburbs, manholes play an important role in ensuring the maintenance activity of the underground channels and passages. Manholes are, however, not kept open but are sealed or locked with covers to give importance to safety and security. Available in solid round-top and square-top variations, recessed manhole covers are also up-and-coming in the industry.

Here, we will put our focus on recessed manhole covers, which are rapidly taking the market forward.

Types of Manhole Cover

With the increasing demand for manholes in different applications, locations of use, and sturdiness and longevity, the best manhole cover manufacturers in India produce such covers in several variations. The most common materials that are used to produce manhole covers and their frames are cast iron, concrete, or a combination (hybrid) of the two materials. Other options for the materials used to cast manhole covers include fibreglass, plastic, and composite. According to BS EN 124: 2015, there are three prominent types of manhole covers.

-

Solid Top Manhole Cover

Solid top manhole covers can be distinguished from the ground surface. Easily identifiable, solid top manhole covers are typically produced out of galvanised steel. These covers are lightweight and anti-skid. Solid top covers are suitable for less congested areas. Such covers may require frequent maintenance too.

-

Ductile Iron Manhole Cover

This kind of manhole cover is exceptionally sturdy since it belongs to the most prevalent categories of manhole covers. These covers are extremely durable, resistant to wear, and do not corrode easily. The ductile iron cover is more durable than the cast iron cover alternative.

-

Recessed Manhole Cover

These manhole covers are often put in locations that can accommodate block paving, cement, and a screed layer for aesthetically pleasing finishes. They are mostly found in areas like pedestrian walkways. Internal manhole covers at hospitals and residential neighbourhoods including apartment complexes are the best places to install recessed covers for manholes.

Key Features of Recessed Manhole Covers

-

Highly durable →

Recessed manhole covers are manufactured using a combination of two materials – which make these manhole covers highly durable. The outer frame as well as the inner filling come together, producing a highly sturdy manhole cover variation.

-

Aesthetically pleasing→

Besides ranking high on the durability scale, recessed manhole covers are aesthetically pleasing. This means, unlike a regular cast iron, galvanised steel cover, these covers can be customised according to the location of their application. As a result, these covers are highly adaptable and are recommended for residential and commercial use.

-

Varied load ratings →

Recessed manhole covers are available according to different load classes or ratings. The load ratings differ as per the scope of application, similar to the other manhole cover counterparts. Recessed manhole cover load ratings have been discussed below.

-

Anti-skid features →

Because of the texture and the design, recessed covers have certain defined grooves and slots — which gives them the anti-skid feature.

-

Locking mechanism →

These manhole covers are also equipped with locking mechanisms, which are designed to be concealed. To ensure safety, these locks can only be accessed and operated by maintenance personnel.

Manhole Cover Load Ratings

Manhole covers come in different shapes, sizes, and load ratings. Load ratings vary depending upon the strength, ability to handle load as well as the material used for manufacturing the manhole covers. Best manhole cover manufacturers in India offer a wide range of load ratings — catering to a variety of applications and needs.

- Light Duty Covers → Suitable for use in residential or institutional complexes, these manhole covers are ideal for areas that get light or occasional traffic – of up to 25 kN of load.

- Medium Duty Covers → Medium-duty covers, which can take 100 kN of load are ideal for service roads, pavements, and car parking areas too.

- Heavy Duty Covers → Capable of withstanding up to 200 kN, these heavy-duty manhole covers are capable of handling and withstanding heavy pressure and extreme speed from vehicular traffic. Such covers are often spotted in between high vehicular inflow because of their sturdy build and longevity.

- Extra Heavy Duty Covers → A weight of about 350kN can be supported by an extra heavy-duty manhole cover. They can be used on carriageways in commercial, industrial, and port areas. Moreover, their applications are also common in areas close to warehouses or godowns where truck loading and unloading operations are frequent, and with slow to fast-moving vehicular traffic.

Recessed manhole covers have truly transformed the general perception of manhole cover appearances. Aesthetically pleasing, durable, and serving their purpose, these covers are set to become one of the most sought-after products in the casting industry.